Simufact Engineering has unveiled their Simufact Additive, a new software solution for the simulation of metal additive manufacturing processes in delivering what the company describes as ‘right first time’ optimization of laser powder bed fusion processes. Features include:

- Simulation of all the key process steps, starting with printing, and followed by heat treatment, cutting the part off the build plate and removal of support structures.

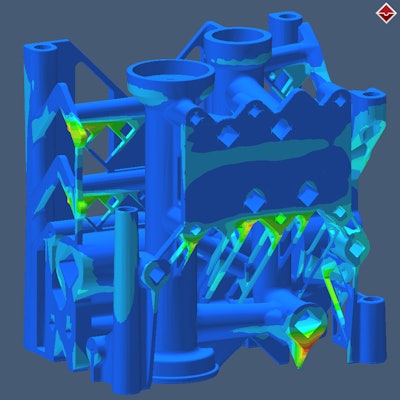

- The initial release will predict the final distortion and residual stresses of metal 3D printed parts.

- The modelling is carried out using CAD data in a newly developed Graphical User Interface environment aligned with the real process work flow. The general process is defined by determining the part and support components through to definition of manufacturing parameters up to the analysis settings.

- The software hopes to compensate the distortion, minimize residual stresses and optimize the process parameters.