To be a long-term success in manufacturing requires an ability to always look forward. That means everything from anticipating customer demands and industry trends to embracing the use of new technologies and tools.

For many manufacturers that means improving operations by implementing a digitalization strategy that utilizes sensors and cloud computing to connect equipment, collect data, and then analyze that data. In fact, a survey conducted by the consultancy PwC found that 72 percent of manufacturers were “dramatically” increasing their level of digitalization and expected to be considered digitally advanced by 2020—up from just 33 percent of manufacturing companies that would deem themselves digitally advanced today.

Nobody would argue that a perpetual quest to improve via future-forward techniques and technologies is a bad move. But it’s also important to remember the importance of getting the most out of the tools manufacturers already have. Case in point: Maximizing the value of a CRM.

Accurate Demand Forecasting

By now, most successful manufacturers have already implemented and are benefitting from the use of a CRM. Not surprisingly, one big reason CRMs have become a go-to tool for manufacturers is because they provide a way for companies to get a glimpse into the future and make strategic decisions based on what they see.

For example, a powerful CRM allows manufacturers to forecast sales based on real numbers instead of extensive research or best guesses. This is invaluable. By having forecasting that has a firm foot in the real world, manufacturers are able to order the right amount of raw materials they need to meet the demand of customers. Not only does access to the proper amount of raw materials needed to fill orders help reduce waste, CRM-enabled forecasting provides strong indications of where market demand is headed in the future. This allows manufacturers to make any retooling or adjustments required to produce the products that are increasingly in demand.

A Central Repository for Company Data

CRMs can also be used as a manufacturer’s central repository for information, helping to break down the silos that make it hard for sales, customer service and operations to communicate consistently with customers and suppliers. This can lead to mixed messages and a diminished level of trust. But when a CRM is integrated with a manufacturer’s ERP system, there is visibility across a manufacturer that ensures you are speaking with a consistent voice and are relying on the same information.

Just as important, a well-maintained CRM that serves as a single source of truth within a company allows sales reps and customer service personnel to earn the vital credibility that comes when information they provide about the status of an order is reliably accurate. All of these benefits of a powerful CRM also help employees work more efficiently. There’s no more wasted time chasing down information about whether or not an order shipped and no unhelpful lag time between initial contact with an interested prospect and a follow-up.

Data Integrity Is Critical to Maximizing a CRM’s Benefits

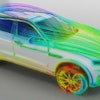

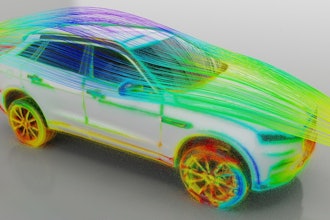

Clearly, many manufacturers understand these benefits and have deployed CRMs to achieve them. Unfortunately, the presence of a CRM is not enough by itself to empower manufacturers to be more responsive and customer-focused. Like a vehicle or a skilled athlete, a CRM can only achieve its potential with the right fuel— and in the case of a CRM, that fuel is comprehensive and current data. Only when employees consistently input data into their CRM is it possible to reap the many rewards that come from having a well-fueled machine.

When this is done right, a CRM has data integrity. And while it would be reasonable to think that employees would be eager to do their part maintaining and fine-tuning a tool that can help them perform their jobs better, that simply does not happen all of the time. It takes training and incentives to encourage employees to reliably input the information that will ensure a CRM has data integrity.

While some manufacturers may be tempted to pursue improved data integrity with a top-down approach that requires employees consistently input data into a CRM, that heavy-handed philosophy can risk backfiring and alienating employees. And what manufacturer wants to alienate good employees, particularly when the competition for labor is so fierce?

Using Gamification to Ensure Data Integrity

A better approach is to tap the power of gamification to motivate employees to diligently pursue improve data integrity. Anybody who has teenage children will instinctively know the power of gaming and competition. A real-life example of how this works can be seen on the factory floor of some Ingersoll Rand facilities.

The company taps the innate competitiveness of its workforce by tracking the speed at which they complete tasks using software attached to smart screwdrivers. When one team of employees finishes its tasks before another, the winning squad is rewarded with a financial bonus or paid time off. The results of competition are shared publicly, which provides the recognition and acknowledgement many workers crave.

Not all manufacturers will decide that their culture is right to tie rewards to data integrity with the help of gamification. But it may very well turn out that games promoting improved data integrity will only be necessary a handful of times. When employees realize how much better they can do their jobs with a fueled up CRM, extra encouragement won’t be necessary.

Allen Swope is IT Director at Clear C2.