In just a few short years there has been a significant shift from the ‘classic’ ERP solutions of the past to new, decidedly ‘modern’ ERP solutions. Modern digital ERP tools are adaptable solutions that can enable savings for manufacturers and support greater cost responsibility alongside enterprise-wide visibility and coordination. The difference between new and old is staggering, but these changes hold more value than they initially let on.

Enabling Greater Cost Responsibility

In addition to traditional ERP functionality, today’s ERP solutions bring reduced costs and added value over earlier systems. In recent years, ERP has shifted from a solely on-premise solution to a system that can be deployed through a hybrid approach across multiple environments, spanning internal (on-premise) and external (cloud-based) locations.

Integrating cloud-based solutions allows manufacturers with warehouses, factories and customer services centers spread out across the country (or even the world) to share actionable data in real-time. These data sharing capabilities empower employees at all levels to make educated decisions that eliminate errors, duplications and overlooked cost-saving opportunities, providing each member of your team a greater role in cost responsibility.

Modern ERP solutions delivered via the cloud are transitioning ERP from a single fixed capital expense to an operating expense divided across time, reducing overhead and making it more affordable and accessible for manufacturers of all sizes. The transition offers manufacturers and other organizations more financial flexibility, enabling them to take advantage of the newest technology solutions and capabilities without allocating significant funds upfront. This shift from a capital IT investment to a distributed operating expense in turn frees up cash for other projects and investments that drive revenue and growth.

A range of platform delivery options also has cascaded effects for associated expenses. In line with spreading out the costs of ERP itself, related costs such as hardware maintenance and data center operational expenses are also dispersed over time. Leveraging private cloud environments and sharing infrastructure reduces costs even further as other cloud tenants share in the coverage of maintenance costs. In addition, manufacturers that opt for cloud-based ERP options can also take the costs of data center hardware repair and upgrades off their plates, as their hosting partners take the lead and keep servers and other key components in top shape.

Optimizing Internal and External Interoperability

By improving internal data access and interconnectivity, modern ERP solutions enable greater information responsiveness. For example, with access to up to date insights, manufacturers can track anything from commodity and materials prices to supplies shipments, helping them become more agile and adapt as conditions change. Serving as a shared system of record, modern ERP tools help keep all parties in the supply chain (businesses, suppliers and customers) on the same page with costs and timing in real-time, eliminating confusion and ensuring all parties are aligned.

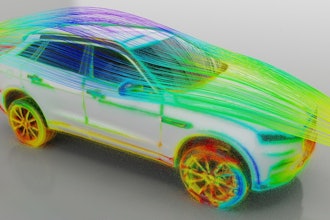

Better information access allows manufacturers to trade reactive choices for predictive decisions, saving money in the long run and allowing businesses to foresee future challenges and prepare accordingly. With predictive supply chain insights, an automotive manufacturer could predict a future delay in production or shortage of a crucial part, and could increase orders accordingly to avoid a material shortage. Rather than reacting after the issue occurs and scrambling to find another supplier, the manufacturer is able to avoid the issue and similar challenges in the future altogether by predicting likely scenarios and circumventing potential bumps in the road.

Driving Collaboration

Within organizations, modern ERP solutions enable better and more efficient collaboration. For example, a single shared data source that allows all sides of the business, including management, finance, delivery and other vital departments, to check the status of a project in real time. In turn, this enables various teams to work in tandem, avoiding duplication of efforts and eliminating unnecessary costs. Integration of world-class business analytics software on top of an organization’s data sources also helps realize the vision of a digital boardroom, allowing technology to have an impact at the highest levels of the business.

Outside of a business, ERP-driven interconnectivity can support improved collaboration and information exchange between organizations, providing suppliers and clients with greater access to information and facilitating the interchange of insights. Taken a step further, this interoperability can help reduce the costs of less value-added projects. For example, rather than calling customer service for a status update, a self-service portal connected to a business’ ERP system can enable customers to access real-time project information, sparing both parties time and cutting down internal support costs.

As customer demands and competitive pressures continue to rise, businesses across the manufacturing industry will need the speed and functionality of modern ERP solutions to confidently make decisions in real-time. Modern ERP solutions help drive down technology costs and enable greater visibility and value, making processes more cost responsible and improving the flow of information, both internally and with customers and suppliers. To succeed in today’s business environment, companies need tools that streamline workloads, empower organizational interconnectivity and allow for greater financial flexibility. Modern ERP helps achieve this, and manufacturers will only see more benefits as technology continues to advance.

Brian Everett is an Industrial Solution Developer at itelligence.