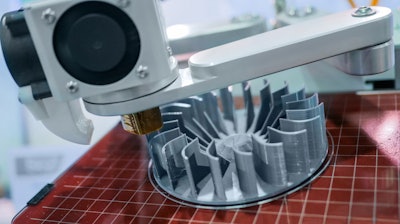

Everything evolves – and in the world of technology, things evolve quickly. The phone in your pocket is more powerful than the computers of your youth. The 4K TV in your living room delivers resolution far beyond that of a standard-definition set. And the capabilities and understanding of additive manufacturing (AM) – also known as industrial 3D printing – have advanced dramatically over the past decade.

As a result, AM has become a transformative force in a wide array of industries. AM applications in aerospace, automotive, healthcare, and consumer goods have created entirely new markets, previously unimaginable product performance, and new benchmarks for production efficiencies. From sustainability to lower cost-per-part to mass customization to innovative design to part consolidation, AM has made a reality of what was previously impossible.

However, AM is also a victim of obsolete opinions and assumptions. Imagine if everything you knew about today’s phones or TVs was based on information from a decade ago. Outdated ideas about AM’s limitations, cost, quality tradeoffs, and potential applications often prevent companies from beginning their industrial 3D printing journey – even within organizations that could benefit from AM the most.

Let’s explore some of the lingering myths that have been made obsolete by AM’s rapid evolution. These four bothersome “bottlenecks” to AM adoption aren’t really bottlenecks at all - they have been solved by the maturity of AM.

Myth: AM is for prototypes, not production

3D printing functional prototypes is a key use of the technology! But using AM for production applications is now nearly as common as prototyping applications. According to Sculpteo’s State of 3D Printing 2020 report, around half of respondents use AM for production, and businesses already using AM have made production a top priority. To be fair, not every production application is a perfect fit for 3D printing, but only a part-screening initiative (application selection) can make that determination.

Myth: AM is slow

There are many examples of AM greatly reducing the time from idea to production, and there are many examples of applications that only 3D printing can generate. Ultimately, the speed gap between AM and traditional manufacturing is much smaller than you might think.

According to this 2019 Deloitte report on AM, high-volume AM production speeds are often mere seconds slower than traditional manufacturing. As with any application, AM isn’t always the best solution. But AM’s speed has also delivered faster and nimbler solutions that haven’t been possible before. Ultimately, printing is a small fraction of the production lifecycle. When you consider the entire end-to-end manufacturing journey, AM accelerates prototyping, design iterations, assembly requirements, time-to-market, inventory management, and supply-chain efficiency.

Myth: AM is always more expensive than traditional manufacturing

Not so! AM represents a significant cost reduction compared to traditional manufacturing in many scenarios. The most common example is on-demand production: AM delivers as-needed production runs, which enables lower inventory management costs and simpler supply chains. Furthermore, AM can reduce the need for different machines to produce different parts, and has the potential to lower the costs associated with product assembly and supply-chain logistics.

Myth: All manufacturing is dirty, wasteful, and harmful to the environment

By nature, additive manufacturing is responsible manufacturing. Subtractive manufacturing involves cutting, chipping, shaping. It may take 10 pounds of material to make a 3-pound object, while AM would use 3 pounds of material to make the same object. AM is also making big gains in material recyclability, reduced energy usage, and bio-sourced and recyclable polymers.

Furthermore, AM’s ability to produce on-site, on-demand applications reduces warehousing and transportation needs – and more than 80 percent of harmful emissions and 90 percent of a manufacturing operation’s impact on the environment are related to those supply-chain requirements. Consider a single, 3D-printed latch on an aircraft: It’s cheaper to produce, lighter in weight, and when amortized across an airline fleet, can save $20 million while reducing CO2 emissions by 8,000 lbs. per plane per year.

So, how are these myths relevant to your organization? According to this this McKinsey and Company report, “first-mover” manufacturers that have adopted AM are reaping the rewards of high ROI and economic gains throughout their business.

---

Greg Hayes is a Senior Vice President of Applied Technology at EOS.