Taking inspiration from last Thanksgiving’s Supersonic Turkey Cooking (STC) using Ansys Fluent by CFD Specialist Alex Lefebvre, I developed a handheld microwave emitter and simulated the feasibility of using it to cook this year’s Thanksgiving turkey.

A traditional microwave oven utilizes a magnetron to convert power into microwaves (the common frequency of microwave ovens is 2.4GHz). These microwaves travel from the magnetron to the oven chamber through a waveguide (think air ducts for RF signals).

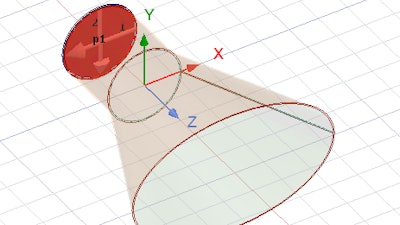

To create a handheld version of a microwave, I utilized the Antenna Design Toolkit within Ansys HFSS. Using this toolkit, I selected an elliptical horn antenna because it includes a waveguide section and had the directionality that would ensure I wasn’t going to cook my hand alongside the turkey. All I needed to do to generate my antenna model was to then input the desired operating frequency of 2.4GHz and let the HFSS toolkit take care of the rest.

Fig 1: Ansys HFSS Antenna Toolkit SetupAnsys

Fig 1: Ansys HFSS Antenna Toolkit SetupAnsys

With the waveguide/horn antenna complete, the rest of the HFSS model was created. The simulation was performed using 500W of power applied to the wave port on the antenna input. In Figure 2, one can observe the fields propagating from the emitter reaching field strengths more than 5000 V/m. This is seriously something you should not try at home.

Fig 3: Ansys Icepak Results (500W)Ansys

Fig 3: Ansys Icepak Results (500W)Ansys

Fig 3: Ansys Icepak Results (500W)Ansys

Fig 3: Ansys Icepak Results (500W)Ansys

When microwaves are absorbed by the turkey, the energy contained within the RF fields are converted into losses in the form of heat. Using the simulated electromagnetic losses absorbed by the turkey, Ansys Icepak was used to solve the steady-state temperature of the turkey due to the microwave emitter.

The results of our 500W simulation (Figure 3) show that the turkey breast will reach a temperature over 500 degrees Fahrenheit. A bit overdone for my taste. We also see that the underside of the turkey is still raw.

It is apparent that the direct radiation of the microwaves is causing an uneven distribution of fields which in turn causes these extremes in the turkey’s temperature.

A metallic vessel was then created to prevent direct RF radiation to the turkey while also trapping the microwaves around the turkey. The power level was also reduced from 500W to 300W.

In Figure 4, one can see that the fields deflect off the top and continue to bounce around within the vessel. Similar to the internal walls of a traditional microwave, this effectively acts as an oven containing the microwaves (our source of heat).

Fig 4: Ansys HFSS RF Simulation (w/Vessel @ 300W)Ansys

Fig 4: Ansys HFSS RF Simulation (w/Vessel @ 300W)Ansys

Fig 4: Ansys HFSS RF Simulation (w/Vessel @ 300W)Ansys

Fig 4: Ansys HFSS RF Simulation (w/Vessel @ 300W)Ansys

Repeating our linked simulation in Icepak shows that we have achieved the target internal temperature of 165 degrees Fahrenheit for the safe consumption of turkey.

However, it can be observed in Figure 5 that the turkey breast still has excessive heat. It is expected that further tuning of the vessel’s deflector is necessary for those that desire extra-extra-crispy turkey this Thanksgiving. Stay safe, do not take apart your microwave and try to do this (seriously), and have a great Thanksgiving.

Fig 5: Ansys Icepak Results (w/Vessel @ 300W)Ansys

Fig 5: Ansys Icepak Results (w/Vessel @ 300W)Ansys Fig 5: Ansys Icepak Results (w/Vessel @ 300W)Ansys

Fig 5: Ansys Icepak Results (w/Vessel @ 300W)Ansys

About the Author

Matthias Laurich is an electromagnetics simulation specialist at Rand Simulation.

As an Electromagnetics Simulation Specialist, Matthias works with customers to achieve their goals through identifying critical needs and delivering the correct solutions through simulation.

Prior to Rand Simulation, he was a Sr. RF Engineer at Digi International Wireless Design Services. His consulting background and EMC knowledge has assisted many clients overcome significant EMI failures and gotten them back on the right track in their development.

Matthias has a MSEE degree from the University of Minnesota with a focus on antenna design, power electronics, and sustainable energy systems.