The digital thread is increasingly part of many companies’ long-term plans for digitizing core processes related to developing, producing, selling, and supporting products. While definitions vary, we at Razorleaf view the digital thread as a set of connected records of all the data and activities that define a product. Making activities part of the digital thread definition is key.

Many think of product-related data as the backbone of the digital thread—as they should—but the approvals, project tasks, research, decisions, and other workflows that go into defining the product must also have representation for context.

Connectivity of all these records and processes is central to the digital thread premise. The fact that you are relating valuable data points about the product is what makes it a thread, enabling understanding of such activities as what research led to certain product decisions or what iteration was tested, resulting in a series of design changes. The digital thread delivers results when you can determine which decision led to what particular design outcome, and you can only do that if everything—both data and activities—are truly connected.

With the right elements in place, the digital thread provides invaluable insights. Beyond decision support, the digital thread can facilitate automation as well as forensic applications—for example, tracing and tracking a product’s origin as well as its usage, impacts, and other details to prove authenticity or to get to the root cause of quality problems before they mushroom into a full-blown crisis.

Enter the Model-Based Enterprise

While not a requisite for bringing the digital thread to life, the model-based enterprise brings a layer of richness to the data and ensures it can be easily shared across functions to deliver value at every juncture of a product’s lifecycle. With a model-based digital thread, engineers, manufacturing specialists, and sales people are working off the same set of data and activities, allowing them to make better decisions and predict behavior that can drive automation.

Embracing MBE means a shift away from the conventional drawing-centric world to a model-based approach where people work with shared data that can serve multiple purposes. In comparison, with a traditional approach, different roles and departments work with purpose-built drawings, data, and materials that often have to be reentered or translated to be shared.

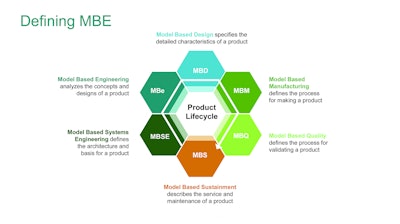

While engineers tend to equate models with the 3D mechanical types employed by CAD, MBE has a much broader interpretation.

There are many types of models in this world, including math models, state machine models, behavioral models, logical models, and others. There are also multiple models for a single component or element of a product — for example, a design specification model of a motor might depict it as 3.2 pounds while a behavioral model would analyze the thermal characteristics of that same motor while running, and a marketing model would include a rendering used as part of the sales cycle.

MBE also covers the continuum of the product lifecycle: model-based design would specify the detailed characteristics of the product while model-based systems engineering defines the architecture and basis for the offering, and model-based manufacturing covers processes for producing said item, and so on.

In a traditional world, there could be different drawings or views of products and processes that are relevant for specific stakeholders. Even when using PDM, PLM, or other tools to manage product-related data and processes, it is still challenging to keep everyone working on the same data set and it can be an arduous process to sync updates across the chain.

Not so with MBE. With everyone working off the same shared model, different users can pull the information they need when they need it and it becomes much easier to handle changes.

Strengthening the Digital Thread

In the traditional drawings-based scenario, a digital thread might consist of a set of requirements stored in an Excel spreadsheet, some calculations done in MATLAB, a report highlighting design decisions written up in Word, a project plan, and a thermal analysis model done in ANSYS. While the digital thread connects links, the dots exist in different files, formats, and reports, which makes it difficult to manage and share effectively.

Now envision that same set-up as a model-based approach. Each deliverable such as the Excel spreadsheet or report document is broken down into constituent pieces of data and parameters that can then be mapped, linked, and leveraged by other steps in the workflow. By doing so, the model-based data comprising the digital thread can be connected more richly and reused across workflows.

While MBE makes sharing a single model across domains far easier, it also aids in sharing and connecting the individual model parameters, helping to close loops and create opportunities for automation.

Making MBE Work

Like most major transformations, the shift to MBE is as much about organizational and cultural change as it is about technology. Organizations need to strike a balance between being passionate about the possibilities of a model-based approach with the practicality that they are deriving real business value from it. As such, it becomes an exercise in change management and fostering user adoption of the MBE approach—not a sales pitch on a specific set of tools.

As part of the transition, it’s critical not to rip up and replace old processes and CAD drawings, but to identify areas where MBE can deliver business value and build and evolve from there. Working with partners to create a roadmap for transitioning to MBE can facilitate this process, helping to assess where the organization is today, what it wants to achieve, prioritizing goals, and decomposing those goals into achievable strategies, tactics, and next steps.

In addition, PLM, long promoted as the storehouse of product-related data, should play a similar role in the MBE, serving as the nexus for feeding model-based data to other systems and other constituencies. At the same time, integration techniques need to be part of the mix to understand the product model and fully leverage it across multiple systems to achieve a full-fidelity digital thread.

There is no singular journey to MBE or the digital thread, for that matter, and the process is on-going. Technology continuously evolves with advancements in areas like artificial intelligence (AI), destined to have significant impact. Companies cannot afford to wait for all the pieces to come together. Instead, it’s important to build a foundation for the digital thread and MBE by focusing on what is most important to the business today with an eye towards evolving to meet what’s on the horizon tomorrow.