There is a consensus on the part of manufacturing executives regarding the strategic importance of Industry 4.0 and the application of Machine Learning to Predictive Maintenance (PdM). At the same time, the implementation of Industry 4.0 practices is also dependent on operations and maintenance employees. Emory University, in collaboration with Presenso - a Machine Learning for PdM solution provider, surveyed over 100 plant level employees to gain an understanding of the challenges they foresee in the implementation of Industry 4.0 PdM. Below is a high-level summary of our findings.

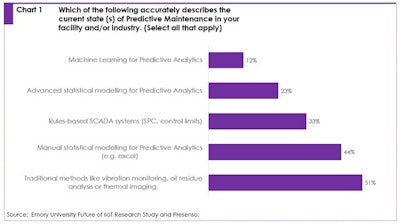

Machine Learning for predictive maintenance is still in its early stage and O&M professionals see limited rationale for adoption. Microsoft Excel is still considered the default tool for process data analytics (44 percent of respondents).

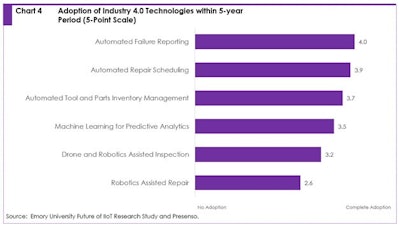

The primary change forecast is in the incremental adoption of the automation of processes and workflows.

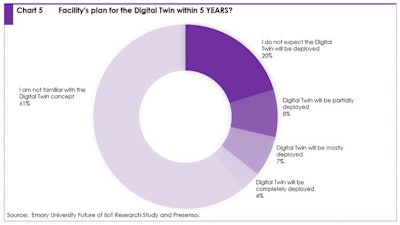

The deployment outlook for the Digital Twin is relatively modest. Interestingly, more than sixty percent of O&M professionals claim that they are not even familiar with the Digital Twin concept.

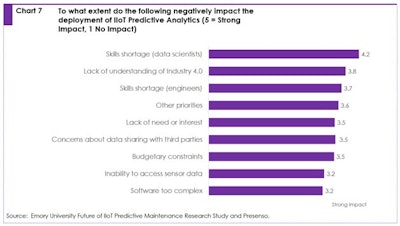

For O&M professionals, the biggest factor preventing the deployment of Industrial Predictive Analytics is a shortage of data scientists, with 44 percent of online survey respondents saying this skill shortage will have a "Strong Impact". The second-highest ranked negative impact on deployment is a lack of understanding of Industry 4.0. Interestingly, the two factors that are least likely to impact deployment of IIoT predictive analytics are the complexity of the software and the inability to access sensor data.

The full report can be accessed at https://www.presenso.com/blog/emory-research.