Robert Everett

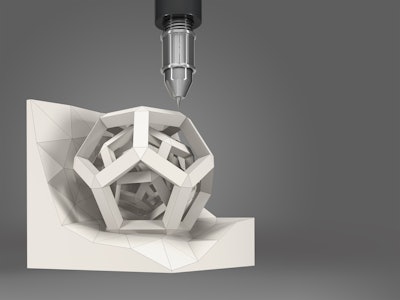

Robert Everett According to statics and research conducted by University College Dublin, students are trained on what is digital manufacturing through various programs. On the study, they get to know better on materials processing using 3D printing and implementation of digital manufacturing within the undergraduate course. Among other studies, present people learned how to use 3D printing technology to fabricate turbocharger turbine parts. Through the research, this blog will help answer three questions that were present throughout the course.

Can Digital Fabrication Increase Student’s Engagement?

Considering that there was an only limited supply of materials required for the entire exercise, trainees were given the freedom to come up with their plan. Due to low-cost funding of the project, each team member was expected to come up with unique manufacturing design to ensure that their team attains the best results amongst the other competing teams. Therefore, due to the high competition between different groups, every participating member had to be hands-on regardless of the limitation in supply to ensure their team the best designs.

In addition to the prior 3D printing knowledge, students were able to show substantial experience in machine handling and print development. Additionally, those with limited experience also has an opportunity to enhance their skills in engineering design and prototyping. Out of the 5.00 possible score, most of them most of them had an average score of 4.16 across all fields.

Is It Possible To Enhance Desire And Enjoyment To Learn Through Self-Guided Training?

In relation to the positive student feedback, it is evident that self-guided learning brings a sense of satisfaction amongst different trainees. Being able to implement ideas and work them out in processing a new design, and finding their way around the industry. Additionally, when students have the freedom of exercising their skills, it becomes easy for them to relate to the work of fabrication.

Having the freedom of navigating your way around a profession allows students to enjoy every learning process. The self-guided learning experience also enhances productivity and guarantees that apart from gaining knowledge students improve their skills and increase experience. Therefore, assuring them that after learning, finding employment will not be difficult.

Does Self-Guided Training Increase Design Understanding And Fabrication Process?

Self-guided learning in manufacturing and design ensures that people working in the industry not only have the relevant skills for the job but also can introduce new models. Additionally, the 3D printing process through self-learning assures users that the market will be filled with competent people attending manufacturing process. Different skills that people bring together based on individual knowledge translate into something better when they combine their efforts. According to an observation from the study, it only takes a few minutes for people with prior knowledge to understand what is expected of them and how to generate a competent design.

Conclusion

Learning digital fabrication through design helps students to set the right foot forward. The experience they get during learning allows them to introduce new skills in the industry. Additionally, during this learning students were able to show different manufacturing designs and 3D printing techniques.

Robert Everett is a digital manufacturer. You can find most of his works at EduBirdie.