In the realm of continuous improvement, changeover time is a subject of much time and energy among manufacturers. This lean manufacturing technique can help you reduce scrap and improve your overall efficiency, and we’ve highlighted seven core steps that we’ve seen our clients use to revise processes.

At Delta ModTech, we produce converting machines that are used to manufacture everything from wound care products to RFID tags to automotive gaskets. These are often short-run, quick-turnaround projects that require our clients to make quick changeovers on their presses.

Following the steps below help converters reduce scrap, cut inventory costs, increase on-time delivery, and the list goes on. For converters, we’ve had a few specific components that Delta ModTech adds to our machines to speed the process even further.

1. Observe the Process

Observe and then document your converting process using video, one-on-one interviews, and in-person observations. Look for variations in the process between the different shifts. You may need to work with union representatives and your internal team if using video.

2. Categorize the Internal and External Activities

There are two types of activities. An internal activity can only be completed when the machine is not running, such as changing a die. An external activity can be performed while the machine is running, such as moving materials next to the press.

3. Convert Internal Activities into External Activities

Can any of those internal activities be done in advance, or at least improve the speed in which they take place? For example, if you need that die, move it near the station while the machine is running.

4. Optimize the Internal Activities

Once the activities are defined, the next step is to find ways to improve them. Often this includes operator activities, such as adjusting settings on a machine. If you can isolate the optimal settings and techniques, you can share it with the entire team.

5. Optimize the External Activities

Look beyond the press. Are there ways to improve those external activities? Perhaps raw materials are moved out of inventory in advance of the press run.

6. Document the New Procedure

Just like you documented the process in step-one, make sure you record any improvements. This will not only lay the groundwork for future improvements, but it will become critical in the event systems crash or paper documentation is lost.

7. Relentlessly Pursue Perfection

Now you’re in the realm of Continuous Improvement. You can improve your quick changeover process on an ongoing basis. The good news is that if you embark on this approach, you can realize changes in as little as 1-2 weeks.

Converting machinery enhancements to improve your process

Delta ModTech machinery has developed specific modules that can speed your changeover. We’ve noted some new enhancements below:

T-Slot Idlers and Clamp-on Idlers

T-Slot idlerDelta ModTech

T-Slot idlerDelta ModTech

Idlers are used to change the web angle, and converters love using them because it provides more flexibility based on the project. Instead of clamping individual idlers, or moving and adding idlers, the T-slot idler and it’s slotted rack allows you to move idlers up and down or left and right in the slot, then quickly lock it in place.

How it helps: Quickly make precise adjustments to the web angle to help with lamination, de-lamination, tension and more.

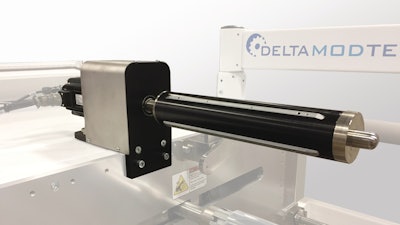

NEW: Movable spindles and Bolt-on Spindles

Movable spindles.Delta ModTech

Movable spindles.Delta ModTech

Everyone wants more spindles on their machines. However, sometimes they can interfere with other web paths within a process. Before movable spindles, you would have to mount more idlers. Now you can simply slide it out of the way.

Bolt-on spindles.Delta ModTech

Bolt-on spindles.Delta ModTech

Bolt-on Spindles can be added anywhere on the front plate of a Delta ModTech machine. You can add pneumatic spindles for simple waste matrix rewinding or add a servo spindle for unwinding and rewinding with precision tension control.

How it helps: Move spindles instantly to adjust web paths or add more winding capacity anywhere you need it.

Die Station Tracking Adjustment

Die station tracking adjustment.Delta ModTech

Die station tracking adjustment.Delta ModTech

Die Station tracking adjustment allows you to move each station cross-web (operator side - machine side).

How it helps: Make small web steering adjustments or move a die cut cross web by simply turning the knob. Each knob includes a digital readout for movement reference.

Hydrajack Bridge Clamps and Pneumatic Nips

Die roller hydrajack pressure adjustment.Delta ModTech

Die roller hydrajack pressure adjustment.Delta ModTech

Operators used to have to use two mechanical bridge clamps to put pressure on die and nip rollers. It was a manual process, and operators had to repeat the pressure set-up (by feel) with every changeover.

Hydrajack Bridge Clamps allow operators to apply uniform pressure across they die with minimal effort. They have a readout so the die pressure settings can be recorded with other process specifications. Hydrajack Bridge Clamps are primarily used on metal-to-metal die cuts due to the high amount of pressure they can apply.

How it helps: Simplify die pressure setup, allows for uniform and repeatable pressure across the roller.

Pneumatic nips

Pneumatic nips.Delta ModTech

Pneumatic nips.Delta ModTech

A pneumatic nip can fully automate nip pressure adjustments for the operator. It also gives you the ability to save a recipe with the parameters, so the pressure can be called up with the rest of the process settings and adjusted by the push of a button.

Our pneumatic nip bridge trucks allow for tool-less installation and removal to further speed up your changeovers between stations.

How it helps: Instant nip setup, allows for uniform pressure across the roller. Easily movable between stations.

This seven-step process can be applied to any manufacturing line to improve your operational flexibility. Learn more about Delta ModTech and how we can solve your toughest challenge.