Tsipora Cohen

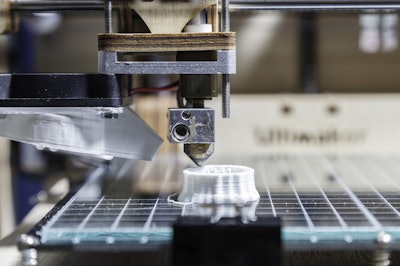

Tsipora CohenAdditive manufacturing (AM), also known as 3D printing, is transforming manufacturing. The process, which involves adding layer-upon-layer of material, is used to fabricate a wide range of objects, including aircraft parts, dental restorations, medical implants, automobiles, jewelry and possibly soon even human tissue.

Additive manufacturing can increase flexibility, reduce costs, and improve product quality. Without the need to weld or attach individual components together there are no weak spots that can be compromised or stressed, reducing the possibility of defects. Designers can make changes with a click of the mouse using CAD software, supporting rapid prototyping, while enabling designs to be verified prior to manufacturing, resulting in fewer production errors. Material costs and waste can be reduced by as much as 90 percent since layers of material are added to create a product instead of cutting away from a larger piece.

Additive Manufacturing on the Shop Floor

According to the National Institute of Standards and Technology, 64.4 percent of the total global market for additive manufacturing is currently produced by companies in the US, establishing the US as the market leader. Beyond hype and proof of concept there are several factories that have produced goods using additive manufacturing.

The U.S. Air Force is utilizing 3D printing to produce replacement parts for old planes much faster and in smaller batches, eliminating the need for a minimum order and the need for warehousing parts. Sportswear company Reebok introduced Liquid Factory — a new technique where liquid material is used to draw shoe components in three-dimensional layers, eliminating the use of traditional molds. San Francisco based Mission Motors has produced a high-performance electric motorcycle comprised of 3D manufactured components.

The industry is still in its early phases and there are many new opportunities for growth. Wohlers Associates found that 135 companies around the world produced and sold industrial AM systems in 2017, up from 97 companies in 2016 with new machines being introduced with open platforms, faster print speeds, and lower prices.

Data Challenges with Additive Manufacturing

Along with all of the opportunities for increased efficiency, there are many new system integration challenges with additive manufacturing. For example, AM production lines can adapt quickly but only at the speed that design specifications and change orders can be transmitted and received. At the same time that data performance is critical, the data transfer needs to be secure, to prevent tampering and to protect intellectual property.

In order to have a real-time analysis of process and product data to improve product quality and manufacturing efficiency, there needs to be feedback from shop-floor additive machines to Manufacturing Execution Systems (MES). The number of units produced and the amount of materials utilized needs to be shared with business management systems, such as CRM, ERP, logistics, warehouse management, and finance, for more effective material, inventory and supplier management. Data about end-user requirements and preferences also needs to be used to enable product personalization.

To make additive manufacturing part of the factory of the future, there needs to be a strong data foundation where shop floor and back office systems can communicate easily. Point-to-point system integrations can be more resource efficient in the beginning, since projects are limited in scope and often internal resources familiar with existing systems can be used. But, in time, as there are more data connections with different e-commerce, CRM, manufacturing and financial systems these projects can multiply rapidly and become unwieldy.

A more resource efficient and practical solution can be a multi-point third party software platform that provides scalability and proven unified data handling. An integration platform can become the backbone of an information hub that can enable rapid integration between shop floor, back office, and partner and supplier systems to provide the AM processes with the data it needs.

The cost advantages, customization capabilities, and green aspects of additive manufacturing will continue to fuel its adoption and rapid growth. As companies take additive manufacturing to the next level to become an essential part of their shop floor, the ability to integrate this specialized manufacturing process with the existing information system will become critical to realize the full benefits. Once there is a free flow of information through every stage of the product life cycle, from design to product delivery, the entire production process can be optimized.

Tsipora Cohen is Global Head of Marketing at Magic Software Enterprises.